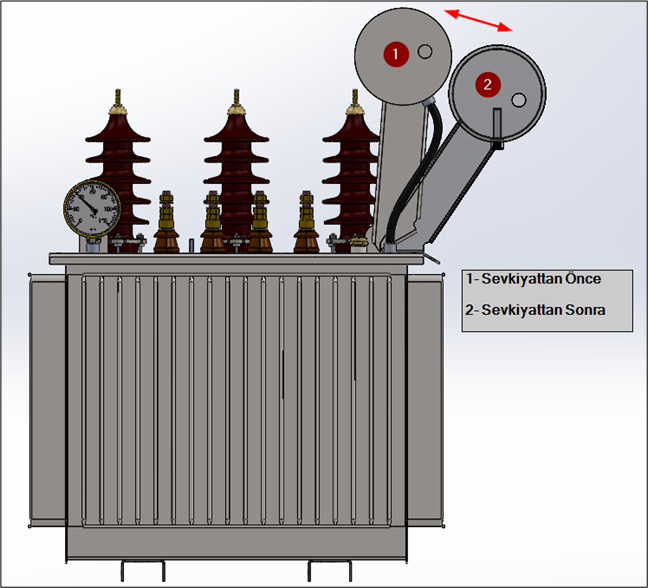

Flexible Expansion Tank Connection

Most distribution transformers still use expansion tanks to accommodate oil expansion and contraction due to temperature changes. We are proud to announce the new DATSAN patent, which introduces a flexible connection between the transformer tank and the expansion tank. The traditional solid steel pipe connection has posed challenges during transportation, handling, and required larger installation spaces.

Minimized Oil Leakage: No welding, reduced risk of leaks

Typically, expansion tanks and transformer bodies are connected by a welded pipe. Since the pipe's thickness is limited and the expansion tank adds its own weight, vibration often occurs at the connection point. This vibration stresses the weld and thinner metal sections, which over time, frequently results in oil leaks.

Lower Transportation Costs: Smaller size, lower costs

In the transformer industry, expansion tanks are usually welded to the transformer tank. To maintain a safe distance between the high-voltage bushings and the expansion tank, the overall transformer length is usually large. However, with our solution, the expansion tank can be folded in the direction of the transformer tank and on its cover, reducing the transformer's overall length. This allows for more compact transportation, lowering space and cost requirements.

Reduced Risk of Damage from Accidental Impacts

It is common for distribution transformer expansion tanks to be damaged during handling and shipping. Because the expansion tank is located on the transformer’s outer edge, it is often struck by crane hooks or comes into contact with other objects during installation and transport. DATSAN’s flexible expansion tank allows users to leave it in the folded position until all work, from manufacturing to final installation, is completed, reducing the risk of damage.

English (English)

English (English)  Turkish (Türkçe)

Turkish (Türkçe)  French (Français)

French (Français)  Arabic (عربي)

Arabic (عربي)